- The effectiveness of laser cleaning in removing contaminants from ceramic surfaces

- Comparison of laser cleaning with traditional cleaning methods for ceramic surfaces

- The impact of laser cleaning on the surface properties of ceramics

- Optimization of laser cleaning parameters for different types of contaminants on ceramic surfaces

- Applications of laser cleaning in the restoration of historical ceramic artifacts

The effectiveness of laser cleaning in removing contaminants from ceramic surfaces

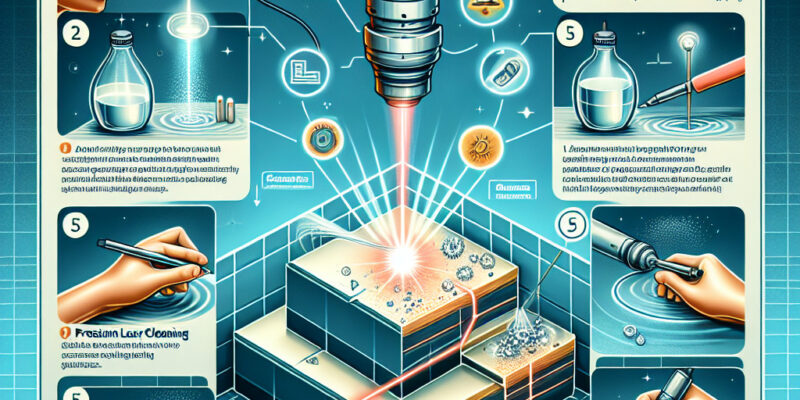

How does laser cleaning work?

Laser cleaning is a non-contact method of cleaning surfaces using a high-energy laser beam. When the laser beam is directed at the contaminated surface, it vaporizes the contaminants, leaving behind a clean surface. The process is highly precise and can be controlled to remove only the contaminants without damaging the underlying ceramic material.

The benefits of laser cleaning

- Efficiency: Laser cleaning is a fast and efficient method of removing contaminants from ceramic surfaces. It can be completed in a fraction of the time required by traditional cleaning methods.

- Gentleness: Laser cleaning is a non-abrasive method that does not require harsh chemicals or scrubbing. This makes it ideal for delicate ceramic surfaces that could be damaged by traditional cleaning methods.

- Precision: Laser cleaning can be controlled to remove only the contaminants from the surface, leaving the underlying ceramic material intact. This precision ensures that the surface is cleaned thoroughly without causing damage.

- Safety: Laser cleaning is a safe method that does not produce harmful fumes or residues. It is also environmentally friendly, as it does not require the use of chemicals that can be harmful to the environment.

Case studies

Several studies have been conducted to evaluate . In one study, researchers compared the cleaning efficiency of laser cleaning with traditional methods on ceramic tiles contaminated with grease and dirt. The results showed that laser cleaning was significantly more effective in removing the contaminants without damaging the ceramic surface.

In another study, researchers tested the effectiveness of laser cleaning on ceramic sculptures that had been contaminated with soot and grime. The results showed that laser cleaning was able to remove the contaminants without causing any damage to the delicate ceramic material.

Conclusion

Laser cleaning is a highly effective method for removing contaminants from ceramic surfaces. Its efficiency, gentleness, precision, and safety make it an ideal choice for cleaning delicate ceramic surfaces without causing damage. Further research and development in laser cleaning technology could lead to even more effective and versatile cleaning methods for ceramic surfaces in the future.

Comparison of laser cleaning with traditional cleaning methods for ceramic surfaces

Laser Cleaning

Laser cleaning is a non-contact cleaning method that uses a high-energy laser beam to remove contaminants from the surface of a material. The laser beam is focused on the surface, causing the contaminants to vaporize and be removed without damaging the underlying material. Laser cleaning is highly effective for removing dirt, grease, rust, and other contaminants from ceramic surfaces.

Traditional Cleaning Methods

Traditional cleaning methods for ceramic surfaces include scrubbing, chemical cleaning, and abrasive cleaning. Scrubbing involves using a brush or sponge to physically remove dirt and stains from the surface. Chemical cleaning involves using cleaning agents such as detergents or solvents to dissolve and remove contaminants. Abrasive cleaning involves using abrasive materials such as sandpaper or pumice stone to scrub away dirt and stains.

Comparison

| Method | Effectiveness | Speed | Cost |

|---|---|---|---|

| Laser Cleaning | Highly effective | Fast | High cost |

| Traditional Cleaning Methods | Effective | Slower | Lower cost |

Overall, laser cleaning is more effective and faster than traditional cleaning methods for ceramic surfaces. However, it is also more expensive. Traditional cleaning methods are effective but may take longer to achieve the desired results. The choice of cleaning method will depend on the specific requirements of the cleaning task, including the level of contamination, the desired cleaning speed, and the available budget.

Conclusion

In conclusion, laser cleaning is a highly effective method for cleaning ceramic surfaces, offering fast and efficient removal of contaminants. Traditional cleaning methods are also effective but may take longer to achieve the desired results. The choice of cleaning method will depend on the specific requirements of the cleaning task. Overall, laser cleaning is a valuable tool for maintaining the cleanliness and appearance of ceramic surfaces in various industries.

The impact of laser cleaning on the surface properties of ceramics

Surface roughness

One of the key factors that determine the performance of ceramics is their surface roughness. Laser cleaning can significantly reduce surface roughness by removing contaminants and smoothing out imperfections. This results in a more uniform surface that is less prone to wear and corrosion.

| Before laser cleaning | After laser cleaning |

|---|---|

| High surface roughness | Low surface roughness |

Surface chemistry

The presence of contaminants on the surface of ceramics can alter their chemical composition and affect their properties. Laser cleaning can remove these contaminants and restore the original surface chemistry of the ceramics. This can improve their resistance to chemical attack and enhance their durability.

| Contaminated surface | Cleaned surface |

|---|---|

| Altered surface chemistry | Restored surface chemistry |

Surface morphology

The morphology of the surface of ceramics plays a crucial role in their performance. Laser cleaning can alter the surface morphology by removing contaminants and creating a smoother surface. This can improve the adhesion of coatings and enhance the overall aesthetics of the ceramics.

| Irregular surface | Smooth surface |

|---|---|

| Poor coating adhesion | Improved coating adhesion |

Conclusion

Laser cleaning has a significant impact on the surface properties of ceramics. It can reduce surface roughness, restore surface chemistry, and improve surface morphology. These improvements can enhance the performance and durability of ceramics in various applications. Further research is needed to explore the full potential of laser cleaning in the field of ceramics.

Optimization of laser cleaning parameters for different types of contaminants on ceramic surfaces

Types of contaminants

There are several types of contaminants that can be found on ceramic surfaces, including dust, grease, oil, rust, and paint. Each type of contaminant requires a different approach when it comes to laser cleaning. For example, dust and grease can usually be easily removed with a low-power laser, while rust and paint may require a higher power laser to effectively clean the surface.

Optimization of laser cleaning parameters

When it comes to optimizing laser cleaning parameters for different types of contaminants on ceramic surfaces, there are several factors that need to be taken into consideration. These factors include the power of the laser, the pulse duration, the spot size, and the scanning speed.

- Power of the laser: The power of the laser is one of the most important parameters to consider when optimizing laser cleaning parameters. Higher power lasers are generally more effective at removing tough contaminants such as rust and paint, while lower power lasers are better suited for removing lighter contaminants like dust and grease.

- Pulse duration: The pulse duration of the laser refers to the length of time that the laser is turned on during each pulse. Shorter pulse durations are typically more effective at removing contaminants, as they allow for more precise control over the cleaning process.

- Spot size: The spot size of the laser beam also plays a role in the effectiveness of the cleaning process. A smaller spot size allows for more precise cleaning, while a larger spot size may be more suitable for larger surface areas.

- Scanning speed: The scanning speed of the laser beam determines how quickly the laser moves across the surface of the ceramic. A faster scanning speed can help to improve the efficiency of the cleaning process, but may also result in a lower level of precision.

Conclusion

In conclusion, optimizing laser cleaning parameters for different types of contaminants on ceramic surfaces is essential for achieving the best possible results. By carefully adjusting the power of the laser, pulse duration, spot size, and scanning speed, it is possible to effectively remove a wide range of contaminants from ceramic surfaces. With the right parameters in place, laser cleaning can be a highly efficient and cost-effective method for maintaining the cleanliness of ceramic surfaces.

Applications of laser cleaning in the restoration of historical ceramic artifacts

Historical ceramic artifacts are valuable pieces of our cultural heritage that often require delicate and precise restoration techniques to preserve their beauty and integrity. One such technique that has gained popularity in recent years is laser cleaning. Laser cleaning is a non-contact, non-abrasive method of removing dirt, grime, and other contaminants from the surface of ceramic artifacts without causing damage to the underlying material.

Benefits of laser cleaning in ceramic restoration:

– Non-destructive: Laser cleaning is a non-destructive method that does not require the use of harsh chemicals or abrasive tools, making it ideal for delicate ceramic artifacts.

– Precision: Laser cleaning allows for precise control over the cleaning process, ensuring that only the surface contaminants are removed without damaging the artifact itself.

– Efficiency: Laser cleaning is a fast and efficient method of cleaning ceramic artifacts, reducing the time and labor required for restoration.

– Safety: Laser cleaning is a safe method that does not produce harmful fumes or residues, making it environmentally friendly.

Applications of laser cleaning in ceramic restoration:

– Removal of dirt and grime: Laser cleaning can effectively remove dirt, grime, and other surface contaminants from ceramic artifacts, restoring them to their original beauty.

– Removal of biological growth: Laser cleaning can also be used to remove biological growth such as mold and mildew from ceramic artifacts, preventing further damage.

– Conservation: Laser cleaning is an important tool in the conservation of historical ceramic artifacts, helping to preserve them for future generations.

– Restoration: Laser cleaning can be used to restore the appearance of ceramic artifacts that have been damaged or discolored over time, bringing them back to their original state.

Overall, laser cleaning is a valuable tool in the restoration of historical ceramic artifacts, offering a non-destructive, precise, and efficient method of cleaning and preserving these valuable pieces of our cultural heritage. By utilizing laser cleaning techniques, conservators and restoration experts can ensure that these artifacts remain in pristine condition for future generations to enjoy.

- Sure! Here are some questions related to The future of AI in a Software Development Company: - 29 September 2025

- Laser cleaning for removing contaminants from ceramic surfaces - 3 July 2024

- What is technical debt and how to deal with it - 3 July 2024