- Introduction to laser cleaning technology

- Comparison of laser cleaning with traditional cleaning methods

- How does laser cleaning work?

- Challenges and limitations of laser cleaning technology

- Training and certification for laser cleaning operators

- Effectiveness of laser cleaning on different types of deposits

- Impact of laser cleaning on equipment performance and longevity

- Importance of regular cleaning and maintenance for industrial equipment

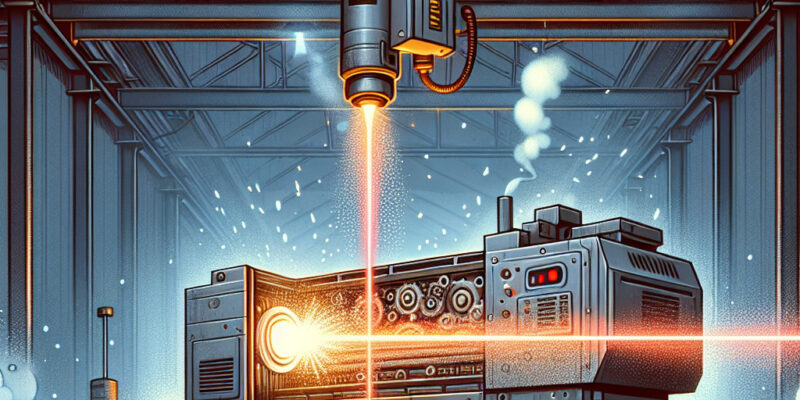

Introduction to laser cleaning technology

Laser cleaning technology is a cutting-edge method used to remove contaminants, coatings, and oxides from various surfaces. This innovative technique utilizes the power of laser beams to vaporize unwanted materials without causing damage to the underlying surface. Laser cleaning is becoming increasingly popular in industries such as automotive, aerospace, and electronics due to its efficiency and precision.

How does laser cleaning work?

– Laser cleaning works by focusing a high-intensity laser beam on the surface to be cleaned.

– The laser beam rapidly heats and vaporizes the contaminants, leaving behind a clean surface.

– The process is non-abrasive and does not require any chemicals or solvents.

Benefits of laser cleaning technology

– Precision: Laser cleaning can target specific areas without affecting the surrounding surface.

– Efficiency: The process is fast and effective, reducing downtime and increasing productivity.

– Environmentally friendly: Laser cleaning does not produce any waste or harmful emissions.

– Cost-effective: Over time, laser cleaning can save money compared to traditional cleaning methods.

🔹 Applications of laser cleaning technology 🔹

– Rust removal from metal surfaces

– Paint stripping from automotive parts

– Cleaning of delicate electronic components

– Restoration of historical artifacts

In conclusion, laser cleaning technology is a versatile and efficient method for removing contaminants from various surfaces. Its precision, efficiency, and environmental benefits make it a valuable tool for a wide range of industries.

#laser #cleaning #technology #precision #efficiency #environmentallyfriendly

Długie ogony:

– laser cleaning technology in automotive industry

– benefits of laser cleaning technology in aerospace sector

– laser cleaning applications in electronics manufacturing.

Comparison of laser cleaning with traditional cleaning methods

Traditional Cleaning Methods

Traditional cleaning methods involve physical or chemical processes to remove dirt, grime, or other contaminants from a surface. Scrubbing, for example, involves using a brush or sponge to physically remove dirt from a surface. Sandblasting uses abrasive materials such as sand or glass beads to remove contaminants. Chemical cleaning involves using solvents or other chemicals to dissolve or break down contaminants.

Laser Cleaning

Laser cleaning is a non-contact method that uses a high-powered laser to remove contaminants from a surface. The laser beam is directed at the surface, where it vaporizes or ablates the contaminants. This process is highly precise and does not damage the underlying material. Laser cleaning is also environmentally friendly, as it does not produce any waste or use harmful chemicals.

Comparison

| Aspect | Traditional Cleaning Methods | Laser Cleaning |

|---|---|---|

| Effectiveness | May require multiple passes to fully clean surface | Highly effective, usually requires only one pass |

| Precision | Less precise, may damage underlying material | Highly precise, does not damage underlying material |

| Environmental Impact | May produce waste or use harmful chemicals | Environmentally friendly, no waste or harmful chemicals |

Overall, laser cleaning is a more effective and environmentally friendly method compared to traditional cleaning methods. It offers higher precision and requires fewer passes to fully clean a surface. While traditional methods may still be suitable for certain applications, laser cleaning is becoming increasingly popular due to its many advantages.

Keywords:

laser cleaning, traditional cleaning methods, surface cleaning, precision cleaning, environmental impact

Long-tail phrases:

comparison of laser cleaning with traditional methods, advantages of laser cleaning, effectiveness of laser cleaning, precision of laser cleaning, environmental impact of laser cleaning

#laser #cleaning #traditional #methods #surface #precision #environmental #impact

Keywords: laser cleaning, traditional cleaning methods, surface cleaning, precision cleaning, environmental impact

Long-tail phrases: comparison of laser cleaning with traditional methods, advantages of laser cleaning, effectiveness of laser cleaning, precision of laser cleaning, environmental impact of laser cleaning

How does laser cleaning work?

- 1. Absorption of laser energy: The laser beam is directed towards the surface to be cleaned, where it is absorbed by the contaminants or coatings.

- 2. Vaporization or ablation: The absorbed energy causes the contaminants to vaporize or ablate, breaking the bond between the material and the surface.

- 3. Removal of debris: The vaporized material is then removed from the surface using a vacuum or compressed air.

- 4. Cleaning verification: The cleaned surface is inspected to ensure that all contaminants have been removed.

Laser cleaning is a versatile and environmentally friendly method that can be used in a wide range of industries, including:

- Automotive

- Aerospace

- Electronics

- Marine

- Historical preservation

Overall, laser cleaning offers a fast, precise, and cost-effective solution for removing unwanted materials from surfaces without causing damage. It is a technology that continues to evolve and improve, making it an increasingly popular choice for industrial cleaning applications.

#laser #cleaning #technology #industrial #surface #contaminants #efficiency #versatile #environmentallyfriendly

#noncontactmethod #vaporization #ablation #removalofdebris #precise #costeffective #evolution #industrialapplications

Challenges and limitations of laser cleaning technology

Challenges

One of the main challenges of laser cleaning technology is the limited range of materials that can be effectively cleaned. While lasers are highly effective at removing contaminants from metals, they may not be as effective on other materials such as plastics or ceramics. This limitation can restrict the applicability of laser cleaning technology in certain industries.

Another challenge is the potential for damage to the surface being cleaned. Laser cleaning can be a very precise process, but if not properly controlled, it can result in damage to the surface due to excessive heat or pressure. This can be particularly problematic when cleaning delicate or sensitive materials.

Limitations

One of the limitations of laser cleaning technology is its cost. Laser cleaning equipment can be expensive to purchase and maintain, making it less accessible to smaller businesses or organizations with limited budgets. Additionally, the training and expertise required to operate laser cleaning equipment can also be a barrier for some users.

Another limitation is the size and portability of laser cleaning equipment. While some smaller, handheld devices are available, larger industrial-grade laser cleaning systems can be bulky and difficult to transport. This can limit the flexibility and versatility of laser cleaning technology in certain applications.

Conclusion

Despite its challenges and limitations, laser cleaning technology remains a valuable tool for removing contaminants from a wide range of surfaces. By addressing these challenges and limitations through research and development, the potential of laser cleaning technology can be further realized in various industries.

#laser #cleaning #technology #challenges #limitations

słowa kluczowe: laser, cleaning, technology, challenges, limitations

frazy kluczowe: laser cleaning technology challenges and limitations, laser cleaning equipment cost, industrial-grade laser cleaning systems.

Training and certification for laser cleaning operators

Why is training important?

1. Safety: Laser cleaning machines use high-powered lasers that can cause serious injury if not handled properly. Training ensures that operators understand how to operate the machine safely and follow all necessary safety protocols.

2. Efficiency: Proper training can help operators maximize the efficiency of the laser cleaning process. They will learn how to adjust settings, position the laser correctly, and troubleshoot any issues that may arise.

3. Quality: Training can also improve the quality of the cleaning process. Operators will learn how to achieve the desired results without damaging the surface being cleaned.

What does training involve?

Training for laser cleaning operators typically includes both classroom instruction and hands-on practice. Topics covered may include:

– Laser safety protocols

– Machine operation and maintenance

– Surface preparation

– Cleaning techniques

– Troubleshooting common issues

Operators may also be required to pass a certification exam to demonstrate their knowledge and skills.

Benefits of certification

1. Credibility: Certification demonstrates that an operator has received proper training and has the skills necessary to operate a laser cleaning machine effectively.

2. Compliance: Some industries may require operators to be certified in laser cleaning to meet regulatory standards.

3. Career advancement: Certification can open up new opportunities for operators, such as higher-paying jobs or supervisory roles.

In conclusion, training and certification are essential for laser cleaning operators to ensure safety, efficiency, and quality in the cleaning process. By investing in proper training, operators can improve their skills and advance their careers in the field of laser cleaning.

#laser #cleaning #operators #training #certification

frazy kluczowe:

– Importance of proper training for laser cleaning operators

– Benefits of certification in laser cleaning operations

– Safety and efficiency in laser cleaning processes

Effectiveness of laser cleaning on different types of deposits

Types of deposits

There are several types of deposits that can accumulate on surfaces, including:

- Dust and dirt 💩

- Rust and corrosion 💀

- Paint and coatings 💪

- Oil and grease 💧

Effectiveness of laser cleaning

Laser cleaning has been proven to be highly effective in removing a wide range of deposits from various surfaces. The high-energy laser beams can easily vaporize contaminants, leaving behind a clean surface without any residue. Laser cleaning is particularly effective on:

- Metal surfaces 💰

- Stone and concrete 💜

- Glass and ceramics 💧

However, the effectiveness of laser cleaning can vary depending on the type and thickness of the deposit. For example, thick layers of paint or rust may require multiple passes with the laser to completely remove them. It is also important to consider the material of the surface being cleaned, as some materials may be more sensitive to the heat generated by the laser.

Benefits of laser cleaning

There are several benefits to using laser cleaning for deposit removal, including:

- No damage to the underlying material 👍

- No need for harsh chemicals or abrasive methods 🔥

- Fast and efficient cleaning process 💡

- Environmentally friendly 🌱

Overall, laser cleaning is a highly effective and versatile method for removing deposits from a wide range of surfaces. It offers numerous benefits over traditional cleaning methods and is becoming increasingly popular in various industries.

#laser #cleaning #deposits #effectiveness #technology

Keywords: laser cleaning, deposits, effectiveness, surfaces, contaminants

frazy kluczowe: laser cleaning on metal surfaces, , benefits of laser cleaning for deposit removal.

Impact of laser cleaning on equipment performance and longevity

In addition to improving equipment performance, laser cleaning can also extend the lifespan of equipment. By removing contaminants that can cause wear and tear on components, laser cleaning can help prevent premature failure and reduce the need for costly repairs or replacements. This can result in significant cost savings for businesses that rely on equipment to operate efficiently.

Furthermore, laser cleaning can also improve the overall efficiency of equipment by ensuring that components are clean and free from obstructions. This can help reduce downtime and increase productivity, leading to improved performance and profitability for businesses that use laser cleaning technology.

Overall, the is overwhelmingly positive. By removing contaminants, preventing corrosion, and improving efficiency, laser cleaning can help businesses maintain their equipment in top condition and extend its lifespan.

#laser #cleaning #equipment #performance #longevity

Keywords: laser cleaning, equipment performance, equipment longevity, contaminants, corrosion, efficiency

Long-tail phrases: impact of laser cleaning on equipment maintenance, benefits of laser cleaning technology, laser cleaning for equipment longevity and performance.

Importance of regular cleaning and maintenance for industrial equipment

Benefits of regular cleaning and maintenance

Regular cleaning and maintenance of industrial equipment offer a multitude of benefits, including:

| Benefit | Description |

|---|---|

| Increased lifespan | Regular maintenance can help identify and address potential issues before they escalate, thus extending the lifespan of the equipment. |

| Improved efficiency | Clean equipment operates more efficiently, leading to increased productivity and reduced downtime. |

| Enhanced safety | Regular maintenance ensures that equipment is in optimal condition, reducing the risk of accidents and injuries. |

| Cost savings | Preventive maintenance can help avoid costly repairs and replacements, saving money in the long run. |

Best practices for cleaning and maintenance

When it comes to cleaning and maintaining industrial equipment, there are several best practices to keep in mind:

| Practice | Description |

|---|---|

| Regular inspections | Inspect equipment regularly to identify any signs of wear and tear or potential issues. |

| Cleaning schedule | Establish a regular cleaning schedule to remove dirt, debris, and other contaminants that can affect equipment performance. |

| Lubrication | Ensure that moving parts are properly lubricated to prevent friction and wear. |

| Training | Provide training to employees on proper equipment usage and maintenance procedures. |

Conclusion

Regular cleaning and maintenance are essential for ensuring the optimal performance and longevity of industrial equipment. By following best practices and implementing a proactive maintenance plan, businesses can reap the benefits of increased efficiency, safety, and cost savings.

#cleaning #maintenance #industrial #equipment #efficiency #safety #costsavings

frazy kluczowe:

– importance of regular cleaning and maintenance for industrial equipment

– benefits of regular cleaning and maintenance

– best practices for cleaning and maintenance

– industrial equipment maintenance tips

– how to clean industrial equipment